Digital radiography (DR) is an advanced imaging technique that produces digital X-ray images directly, eliminating the need for film or intermediate steps like those in computed radiography (CR). As the previous immersive artifact “Digital Radiography with Flat Panel Detectors” notes, DR is used in a wide range of applications, including industrial non-destructive testing (NDT).

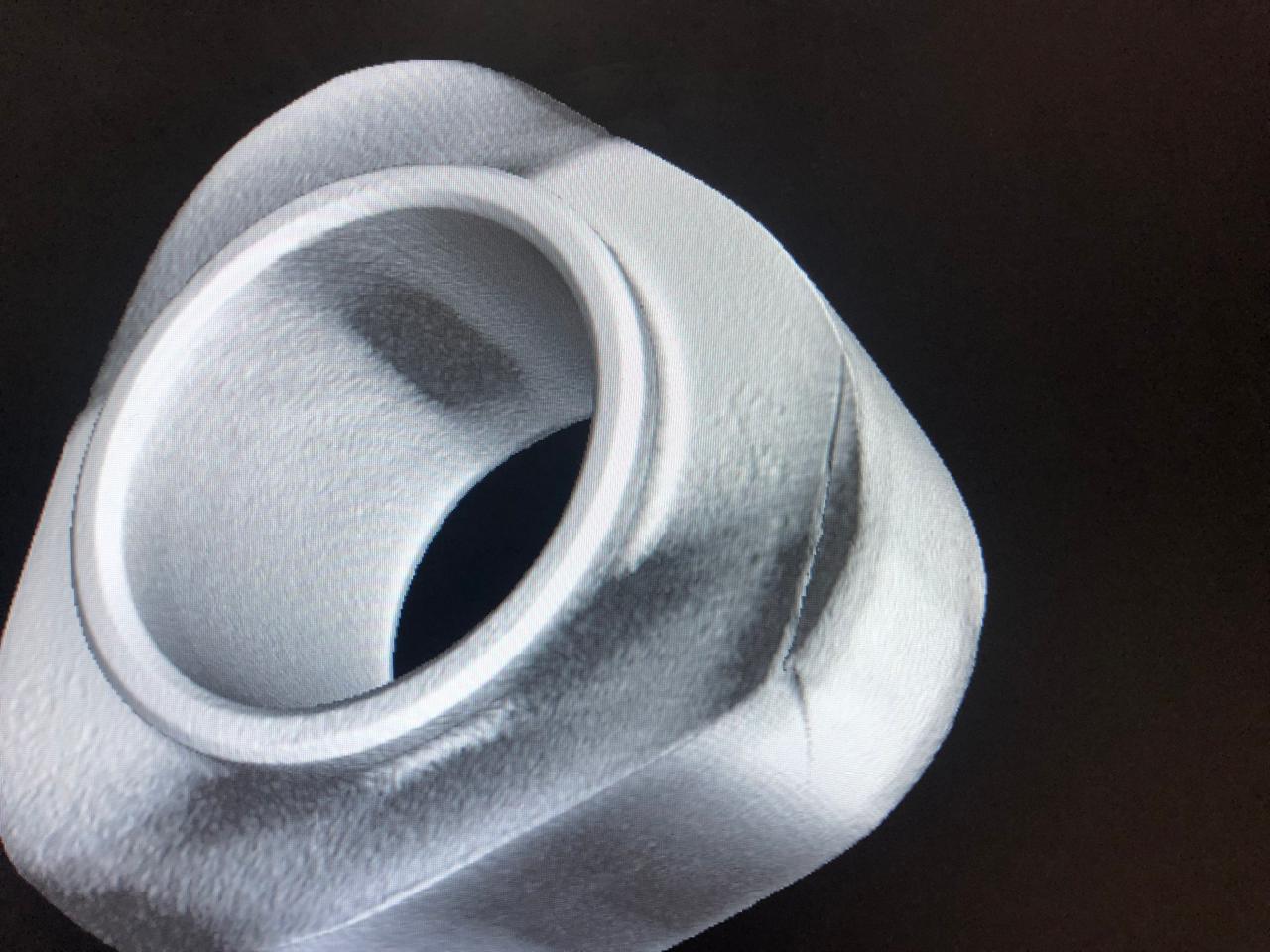

In industrial NDT, DR is used to inspect welds, castings, and other industrial components for defects. This allows for more efficient and accurate detection of flaws compared to traditional film-based radiography. The key component in industrial DR systems is the flat panel detector (FPD).

Flat Panel Detectors in Industrial NDT

Flat panel detectors are solid-state devices that capture X-ray images and convert them into digital signals. In the context of industrial NDT, FPDs offer several advantages:

- Direct Digital Image Acquisition: FPDs capture X-ray images directly, providing immediate image availability. This is crucial in industrial settings where rapid inspection can save time and resources.

- High Image Quality: FPDs offer excellent spatial resolution and contrast, resulting in detailed images that allow for more accurate defect detection and characterization.

- Durability and Reliability: FPDs are designed for continuous use in demanding industrial environments, with robust construction to withstand vibrations, temperature variations, and other challenging conditions.

Types of Flat Panel Detectors Used in Industrial NDT

Both indirect and direct flat panel detectors are used in industrial NDT, depending on the specific application and requirements.

- Indirect Flat Panel Detectors: These detectors use a scintillator layer to convert X-rays into visible light, which is then captured by a photodetector array and converted into a digital signal.

- Direct Flat Panel Detectors: These detectors use a photoconductor layer to directly convert X-rays into electrical charges, which are then collected and read out to form a digital image.

Advantages of Digital Radiography with Flat Panel Detectors in Industrial NDT

- Real-time Imaging: DR provides immediate image acquisition, allowing technicians to quickly assess the quality of a component and make decisions about its acceptability.

- Image Manipulation and Enhancement: Digital images can be easily manipulated to optimize visualization, such as adjusting brightness and contrast, zooming, and applying filters. This can improve the detectability of subtle defects.

- Efficient Workflow: DR systems integrate seamlessly into digital workflows, enabling efficient image storage, retrieval, and sharing. This facilitates collaboration among inspection personnel and reduces the need for physical film storage.

Dose Efficiency: FPDs are more sensitive to X-rays than film, often resulting in lower radiation doses, which can improve safety and reduce inspection time.