Computed Radiography (CR) is a digital imaging technique used in industrial Non-Destructive Testing (NDT) to inspect the internal structure of components and materials. It offers a digital alternative to traditional film radiography, providing advantages in terms of efficiency, image quality, and workflow. While Digital Radiography (DR) with flat panel detectors is also used in industrial NDT, CR offers a distinct approach.

How Computed Radiography Works in Industrial NDT

In industrial CR, an imaging plate (IP) is used instead of traditional X-ray film. The IP is typically housed in a cassette and placed on the opposite side of the inspection object from the radiation source.

- Exposure: The object is exposed to X-rays or gamma rays, and the IP stores the energy absorbed.

- Scanning: The IP is then scanned by a CR reader, which releases the stored energy as visible light.

- Digitization: This light is converted into a digital signal, creating a digital image that can be viewed and analyzed on a computer.

- Erasure: The IP is erased and can be reused for subsequent inspections.

Advantages of Computed Radiography in Industrial NDT

CR offers several benefits that make it a valuable tool in industrial NDT:

- Digital Workflow: CR eliminates the need for film processing, reducing inspection time and eliminating the use of chemicals.

- Portability and Flexibility: CR systems are often more portable than DR systems, and the flexible nature of imaging plates allows them to be used to inspect complex geometries and hard-to-reach areas.

- Wide Dynamic Range: CR can capture a wider range of material thicknesses in a single exposure compared to film, which can reduce the number of exposures needed.

- Image Enhancement: Digital images can be enhanced to improve the visibility of defects.

- Cost-Effectiveness: While the initial investment can be significant, the reusability of imaging plates reduces long-term operating costs compared to film radiography.

Comparison with Digital Radiography (DR) for Industrial NDT

While both CR and DR offer advantages over film radiography, there are some key differences:

- Image Acquisition Speed: DR systems with flat panel detectors provide faster image acquisition than CR, making them more suitable for applications where real-time or near real-time imaging is required. As the “Digital Radiography for Industrial NDT” immersive explains, “DR provides immediate image acquisition.”

- Portability: CR systems are generally more portable than DR systems, especially those with large, rigid flat panel detectors.

- Cost: CR systems can be a more cost-effective digital solution than DR, particularly for applications where high throughput is not the primary concern.

- Resolution: DR systems, particularly direct conversion systems, generally offer higher spatial resolution than CR.

Applications of Computed Radiography in Industrial NDT

CR is used in a variety of industrial NDT applications, including:

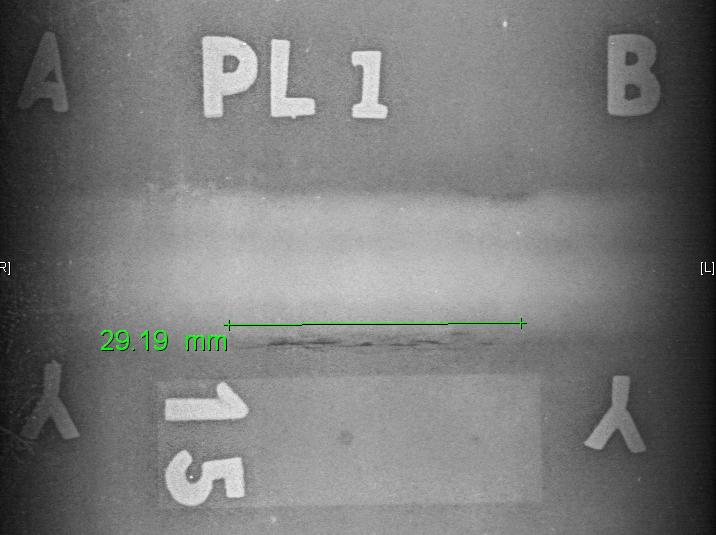

- Weld inspection: To detect defects such as cracks, porosity, and inclusions in welds.

- Corrosion detection: To identify areas of corrosion in pipes, vessels, and other structures.

- Foreign object detection: To locate foreign objects in manufactured components.

- Aerospace inspection: To inspect aircraft components for defects.

- Oil and gas inspection: To inspect pipelines and other oil and gas infrastructure.